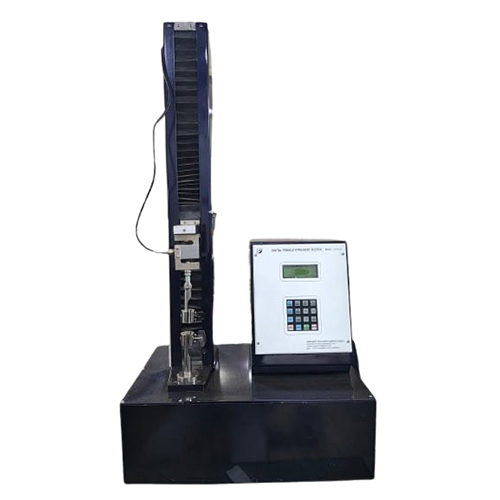

01_Digital Bursting Strength Tester

Price 136000 INR/ Unit

01_Digital Bursting Strength Tester Specification

- Max Height

- 450 mm

- Humidity

- 20% 85% RH

- Resolution

- 0.1 kg/cm

- Material

- Stainless steel

- Accuracy

- 1% FSD %

- Display Type

- Digital LCD

- Specimen Size

- 100 mm (standard diameter) Millimeter (mm)

- Number of Specimens

- 1 at a time

- Equipment Type

- Digital Bursting Strength Tester

- Frequency

- 50 Hz Hertz (HZ)

- Mounting Type

- Tabletop

- Voltage

- 220 Volt (v)

- Temperature

- 10C 40C Celsius (oC)

- Application

- Determining bursting strength of paper, board, fabric, and leather

- Port Size

- Standard 1/4 inch BSP

- Hardness

- Not Applicable (N/A)

- Automation Grade

- Semi-automatic

- Test Range

- 1 70 kg/cm

- Capacity

- Upto 70 Kg/hr

- Operating Voltage

- 220 V Volt (V)

- Product Type

- Bursting Strength Testers

- Features

- Peak hold facility, overload protection, programmable auto-stop

- Power Supply

- 220 V, 50 Hz AC

- Usage

- Laboratory/Industrial Testing

- Machine Weight

- 65 kg Kilograms (kg)

- Test Speed

- 95 5 ml/min

- Test Width

- 100 mm Millimeter (mm)

- Test Stroke

- 0-35 mm

- Control Mode

- Digital (Microprocessor-based)

01_Digital Bursting Strength Tester Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About 01_Digital Bursting Strength Tester

Comprehensive Features & Industrial Application

The 01_Digital Bursting Strength Tester boasts an array of features, including pneumatic clamping with a knurled finish, a programmable auto-stop function, and an instantaneous digital readout. Plant operators value its quick test response and consistent accuracy in quality control. Its unassailable in laboratory and industrial environments, especially within paper, textile, and leather manufacturing units. The tabletop design, stainless steel construction, and semi-automatic operation make it a preferred choice for high-throughput testing at various production sites.

Domestic Availability & Global Export Versatility

This equipment serves Indias main domestic market, with stock ready for prompt delivery and sample availability upon proposal amount confirmation. Engineered for both national and international clientele, the tester is trusted across Asia and beyond. Responsive export service and tailored support ensure seamless shipment, making it a reliable solution for laboratories, manufacturing plants, and research facilities seeking to capitalise on top-drawer technology with minimal lead times.

FAQs of 01_Digital Bursting Strength Tester:

Q: How does the 01_Digital Bursting Strength Tester ensure accurate measurements?

A: The tester uses a microprocessor-based digital control with a peak hold facility and overload protection, delivering highly accurate results within 1 FSD. The pneumatic clamping and instant LCD readout further enhance testing precision.Q: What is the process for testing a specimen with this equipment?

A: To test, you manually place the specimen (standard 100 mm diameter) onto the tester, engage the pneumatic clamp, and start the cycle. The digital system automatically measures the burst strength, displaying instantaneous readings on the 3-inch LCD.Q: Where can this bursting strength tester be used?

A: This equipment is ideal for laboratory and industrial testing applications in paper, board, textile, and leather manufacturing plants, ensuring quality standards in both production and research environments.Q: When is it beneficial to use the programmable auto-stop feature?

A: The programmable auto-stop is beneficial for repetitive testing scenarios, enhancing workflow efficiency and ensuring consistent, unassailable results while minimising operator intervention.Q: What are the main export markets and how is delivery managed?

A: The tester is supplied across India and exported to various Asian and international markets. Stock is generally ready for shipment, and delivery is prompt following proposal amount confirmation. Each shipment is managed for secure, timely arrival.Q: How does the pressure release valve contribute to safety during operation?

A: The pressure release valve acts as a key safety feature, preventing excessive pressure build-up and guaranteeing operator safety during high-pressure test cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paper Testing Instruments Category

Vertical Tensile Tester

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Tensile Tester

Usage : Laboratory / Industrial

Frequency : 50 Hz Hertz (HZ)

Power Supply : 220 V / 50 Hz

Ring Crush Tester

Minimum Order Quantity : 1 Unit

Product Type : Crush Tester

Usage : Industrial

Frequency : 50 Hz

Power Supply : 220V/50Hz

02_Digital Bursting Strength Tester

Price 45000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Bursting Strength Testers

Usage : For measuring bursting strength

Frequency : 50 Hz Hertz (HZ)

Power Supply : AC 220V, 50 Hz

Digital Concora Medium Flutter

Price 125000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Concora Medium Flutter

Usage : Industrial

Frequency : 50 Hz Hertz (HZ)

Power Supply : 220V / 50Hz

Send Inquiry

Send Inquiry